rockwell hardness test blocks aluminum|hrc hrb hra difference : warehouse The indentation measurement helps to calculate the hardness value of the aluminum material accurately. Rockwell Hardness Test For this test, the indenter on the Rockwell hardness testing machine is a tungsten carbide ball of four different sizes or a diamond indenter.

WEB5 de jan. de 2024 · Acompanhe diariamente as garotas anunciarem suas temporadas nesta cidade.

{plog:ftitle_list}

webWatch Brazilian PAWG Vitoria Beatriz Fucks BBC in Hotel video on xHamster - the ultimate archive of free Big Tits & Big Ass HD hardcore porn tube movies!

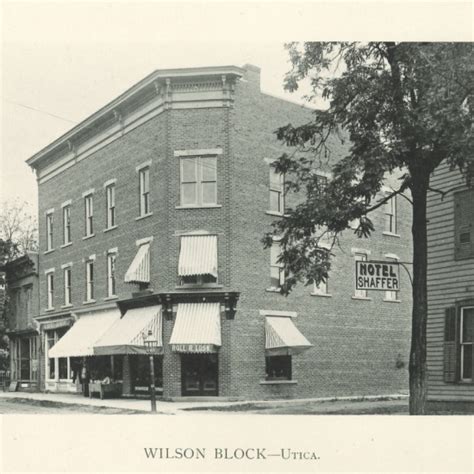

wilson block

Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the hardness of aluminum, brass, and steel. These testers can be used at any angle without affecting accuracy.Rockwell Test Blocks – Superficial Scale. Gilmore Rockwell Hardness Test Blocks (also known as Rockwell Test Coupons) are manufactured and calibrated to current ASTM E-18 and/or .

Wilson Rockwell hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable Rockwell test blocks available. A comprehensive variety of scales and .

how hard is the human resource test

Rockwell test blocks are pieces of steel, brass, or aluminum that have been specially heat treated and calibrated for consistency. By using a test block, Rockwell hardness testers can be calibrated for optimal precision. All of .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the .The indentation measurement helps to calculate the hardness value of the aluminum material accurately. Rockwell Hardness Test For this test, the indenter on the Rockwell hardness testing machine is a tungsten carbide ball of four different sizes or a diamond indenter.Hardness Test Block, Rockwell Hardness Test Blocks , Leeb Hardness Test Blocks, Portable hardness test blocks, Vickers hardness test blocks . Rockwell Hardness Test Blocks (Aluminum): Part No. Description Shape Range Comments; 900330-9414AH: Rockwell B: Square: 80’s: Made in USA: 900330-9414AL: Rockwell B: Square: 50’s:

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels.Typically, you should test and verify your hardness testing system daily against a Newage test block. Newage test blocks for the Rockwell scales include “routine” type blocks and Yamamoto high accuracy test blocks. NIST certification is available for Rockwell C Scale test blocks. Rockwell Test Blocks Features and Benefits

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.B Scale Rockwell Test Block - 5 5 Range is being manufactured due to worldwide material shortages in accordance with ASTM E18 and ISO 17025 standards for quality and uniformity with the highest quality aircraft aluminum.. Each test block has been calibrated on a hardness tester whose accuracy has been verified using N.I.S.T. traceable load and depth measuring devices.

Hardness testing is key in most quality control procedures. That’s why we provide a complete range of hardness testing equipment and accessories for every need, from small lab applications to heavy-duty hardness testing in production. Check out our range of hardness testing equipment to ensure your equipment is up to the task. See our .Please contact us here: 1- 888-400-4243 (USA & Canada) 1-631-321-0160 (International) WESTport Corporation 510 Montauk Highway West Islip, NY 11795 This Barcol Impressor was our tool of choice for aluminum hardness testing. . We have a Rockwell hardness tester at Club DSPORT that we use whenever we need to check the hardness of a material. Unfortunately, the Rockwell tester cannot accommodate larger items. . RB26 and 2JZ Block Hardness Test Nine RB26 and Three 2JZ Blocks . Almost three .A built to last rockwell hardness tester. When you need absolute confidence in your rockwell hardness measurement you want a machine that’s tough enough for the job. The Tru-Blue II will help you to perform thousands of test cycles without the risk of breakdown or failure. Rockwell Hardness Tester Excellence – as standard

Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.Aluminum 6061-T6; 6061-T651. Subcategory: 6000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal. Close Analogs: . Converted from Brinell Hardness Value: Hardness, Rockwell B: 60: 60 Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107 Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa:

Steel: Steel is a common material for hardness test blocks and is often used for Rockwell hardness testing. The blocks can be made from a range of different steel alloys, such as SAE 4130, which has a known .

Hardness Test Blocks and Accessories/Rockwell Hardness Test Blocks/Brinell Hardness Test Blocks/Vickers Hardness Test Blocks/Portable Hardness Test Blocks/Leeb Hardness Test Blocks Please contact us to ensure the part is NOT discontinued prior to ordering. Features Rockwell Hardness Test Blocks – All Scales Superficial

Rockwell Hardness Standard Test Blocks. Rockwell Type Hardness Standards For determining the accuracy of your hardness tester. . Testing Scales. HRA - Cemented carbides, thin steel and shallow case hardened steel HRB - Copper alloys, soft steels, aluminum alloys, malleable irons, etc. HRC - Steel, hard cast irons, case hardened steel and .well hardness test blocks. The standardizing machine differs from a regular Rockwell hardness testing machine by having . Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N). For the Rockwell superficial hardnessBrinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 95 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an .The Vickers hardness test method can be also used as a microhardness test method, . Yield strengths vary from 35 MPa for a low-strength aluminum to greater than 1400 MPa for very high-strength steels. . Common indentation hardness scales are Brinell, Rockwell and Vickers. Rebound hardness. Rebound hardness, also known as dynamic hardness .

Cylinder blocks and crankcases are often cast made of aluminium alloys. Production and Price of Aluminium. Raw materials prices change daily. They are primarily driven by supply, demand and energy prices. In 2019, prices of pure Aluminium were at around 18 $/kg. . Brinell hardness test is one of indentation hardness tests, .Rockwell Aluminum Hardness Test Block 70HRB; Rockwell Aluminum Hardness Test Block 58HRE The blocks with other scales and nominals are available as well. Calibration certificate issued by the third-party metrology laboratory (ILAC) Certificate of origin issued by the Chamber of Commerce and Industry;5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.The previous NIST investigations examined how much a 9 mm thick test block will bend due to repeated indentations and how the bending affects the measurement results. That examination was made by performing Rockwell B hardness tests over the surface of a brass test block, and periodically measuring the flatness of the block’s bottom surface.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

how hard is the hvac epa test

Resultado da Home. Tire a 2ª via da fatura e resolva outras questões rápidas por aqui. Não encontrou o que precisa? 2 VIA DE FATURA. SUPORTE. FALAR COM .

rockwell hardness test blocks aluminum|hrc hrb hra difference